How To Reliably Increase Machine Speed

Learn how we reliably increase machine speed to maximize paper production for paper plants.

Jon Thornham

Founder

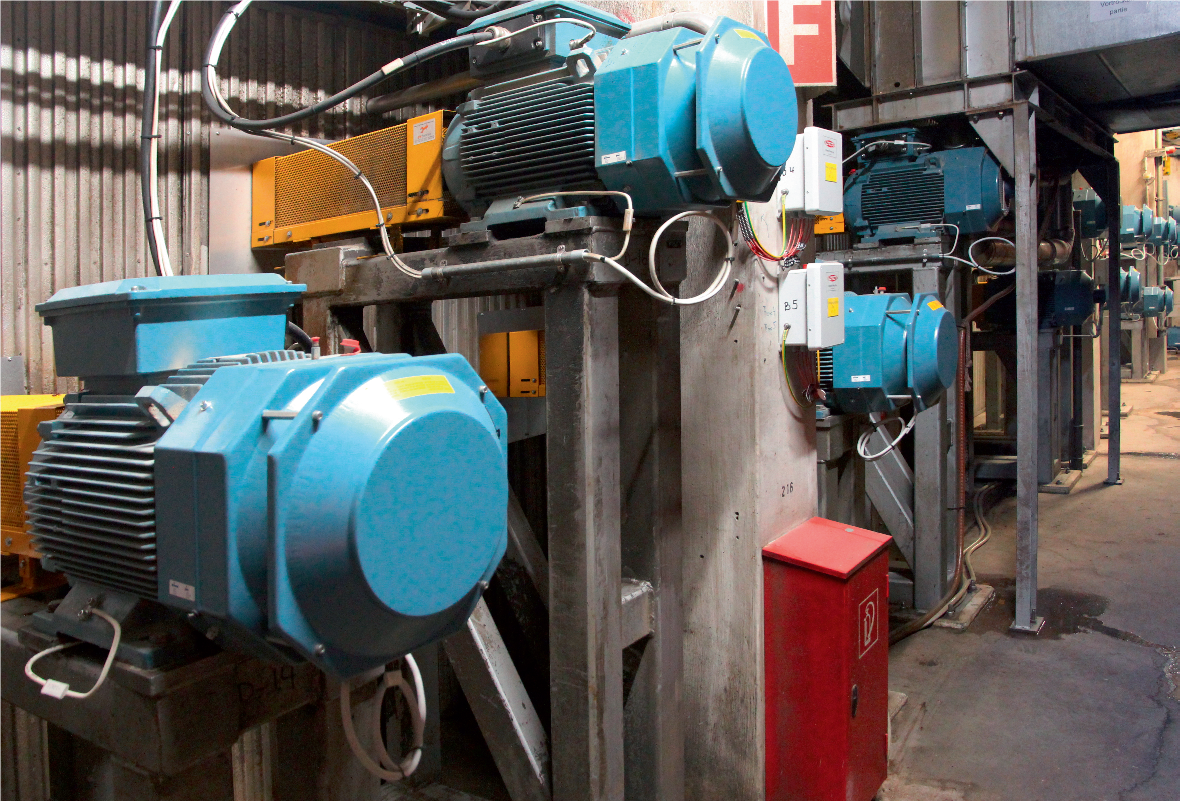

Drive Motor Pedestal

In industrial settings, drive motors and gearboxes play pivotal roles in powering various manufacturing processes. However, one significant challenge encountered is vibration, particularly within the support pedestals that house these critical components. Vibration issues can lead to operational inefficiencies, increased maintenance costs, and potential equipment failures if left unaddressed. This article explores the causes, impacts, and effective solutions for managing vibration problems in industrial drive motor and gearbox support pedestals, with a specific focus on structural modifications to mitigate resonance.

1.

Imbalance: Uneven distribution of mass within the motor or gearbox components can lead to vibration. This imbalance can stem from manufacturing variations, wear over time, or improper assembly.2.

Misalignment: Improper alignment between the motor and gearbox shafts results in angular or parallel misalignment, causing vibrations during operation.3.

Bearing Issues: Defective or worn-out bearings due to insufficient lubrication, contamination, or normal wear can introduce irregularities in rotational movements, leading to vibrations.4.

Resonance: Structural resonance occurs when the natural frequency of the support pedestal coincides with the operating frequency of the motor or gearbox. This resonance amplifies vibrations significantly.5.

Mechanical Looseness: Loose bolts, fasteners, or structural connections within the support pedestal can contribute to excessive movement and vibration.6.

Electrical Factors: Electrical disturbances such as unbalanced voltages, harmonics, or grounding issues can induce vibrations in the motor and gearbox.1.

Increased Wear and Tear: Vibrations accelerate wear on motor and gearbox components, necessitating frequent repairs and replacements.2.

Operational Disruptions: Unplanned downtime due to vibration-related issues leads to production losses and scheduling disruptions.3.

Energy Inefficiency: Vibrations can cause energy losses, affecting overall operational efficiency and increasing electricity costs.4.

Safety Concerns: Excessive vibrations pose safety risks to personnel and can compromise workplace safety standards.5.

Quality Control: Precision and accuracy in manufacturing processes may be compromised, leading to defective products and increased waste.1.

Vibration Analysis: Utilize vibration test equipment such as accelerometers, modal hammers, and multi-channel analyzers to quantify and analyze vibration levels and frequencies, pinpointing the root causes such as imbalance, misalignment, or resonance.2.

Visual Inspection: Regular inspections to visually assess components for wear, misalignment, and structural integrity issues.3.

Thermal Imaging: Detect hotspots indicating frictional heating caused by misalignment or bearing issues.4.

Ultrasonic Testing: Detect early signs of bearing wear and lubrication problems through high-frequency sound detection.Structural resonance is a critical issue that significantly amplifies vibrations in support pedestals. Addressing this requires targeted modifications to the support structure:

1.

Stiffening and Bracing: Reinforce the support pedestal with additional bracing and structural stiffeners to enhance rigidity and reduce flexing. This helps raise the natural frequency of the structure, minimizing resonance with the motor and gearbox operational frequencies.2.

Damping Materials: Integrate damping materials such as rubber pads or isolators between the motor/gearbox and the support pedestal. These materials absorb vibrations and dissipate energy, reducing the transmission of resonance-induced vibrations.3.

Mass Modification: Adjust the mass distribution of the support pedestal or its components to alter its natural frequency away from the critical frequencies of the motor and gearbox. This can be achieved by adding or redistributing mass strategically.4.

Vibration Isolation: Install vibration isolation mounts or pads beneath the support pedestal to decouple it from the surrounding structure. This prevents vibrations from propagating to adjacent equipment or floors.1.

Engineering Analysis: Conduct detailed structural analysis and modeling to predict resonance frequencies and evaluate the effectiveness of proposed modifications.2.

Installation: Ensure modifications are implemented by qualified personnel following industry standards and best practices.3.

Monitoring and Adjustment: Regularly monitor vibration levels post-modification to verify effectiveness. Adjustments may be necessary based on operational conditions and changes in equipment dynamics.Let us help you identify the problem with your drive motors and provide an engineered solution to correct the problem.

A manufacturing facility faced recurrent downtime and maintenance issues due to severe vibrations in their drive motor and gearbox support pedestals, primarily caused by resonance.

1.

Analysis: Detailed vibration analysis identified resonance as the predominant issue affecting operational stability.2.

Modification: Structural engineers reinforced the support pedestals with additional bracing and implemented damping materials to dampen vibrations.3.

Testing and Validation: Post-modification vibration testing confirmed a significant reduction in vibration levels within the critical frequency ranges.1.

Operational Stability: Reduced vibration levels improved operational stability and minimized production interruptions.2.

Cost Savings: Decreased maintenance costs and extended equipment lifespan due to reduced wear on components.3.

Enhanced Safety: Improved workplace safety conditions with lower vibration levels.4.

Productivity Gains: Enhanced production efficiency and product quality with fewer defects and reworks.Effectively managing vibration issues in industrial drive motor and gearbox support pedestals requires a systematic approach, with particular attention to structural modifications aimed at mitigating resonance. By understanding the causes, utilizing advanced diagnostic tools, and implementing targeted modifications, industrial facilities can minimize downtime, optimize operational efficiency, and ensure safer working environments. Investing in structural enhancements not only protects equipment but also enhances overall productivity and reliability, aligning with long-term operational goals and sustainability.

If you are seeing vibration issues on motors, fans, piping, turbines, or structural systems, this article covers only one piece of the diagnostic process. Our comprehensive Vibration Analysis and Engineered Correction guide shows how we use modal testing, ODS, FRFs, FEA, and field measurements to identify root causes and engineer permanent fixes.

Learn how we reliably increase machine speed to maximize paper production for paper plants.

Jon Thornham

Founder

Author Details

Founder

Jon Thornham is the founder of Vibration Engineers, a professional mechanical engineer, and entrepreneur focused on solving complex vibration and reliability challenges across industrial sectors.