FEA, Modal, & Thermal Analysis

If you are experiencing vibration on an existing structure, you may have a resonance issue. When equipment operates at elevated temperatures, thermal growth can make this problem worse. Vibration Engineers redesigns structures to avoid resonance with modal analysis and verifies performance under heat with thermal analysis.

We Can Help

How FEA, Modal, & Thermal Analysis Help

These are the services Vibration Engineers provide using FEA, modal, and thermal analysis to correct vibration and heat-related reliability issues. Learn More

- Impact Testing:

- Complete onsite impact testing of the structure to identify existing natural frequencies.

- Dimensional Assessment:

- Perform dimensional assessment using a laser scanner to create a 3D model of the existing structure.

- Conceptual Sketches:

- Provide conceptual structural sketches of a proposed solution for review with the facility.

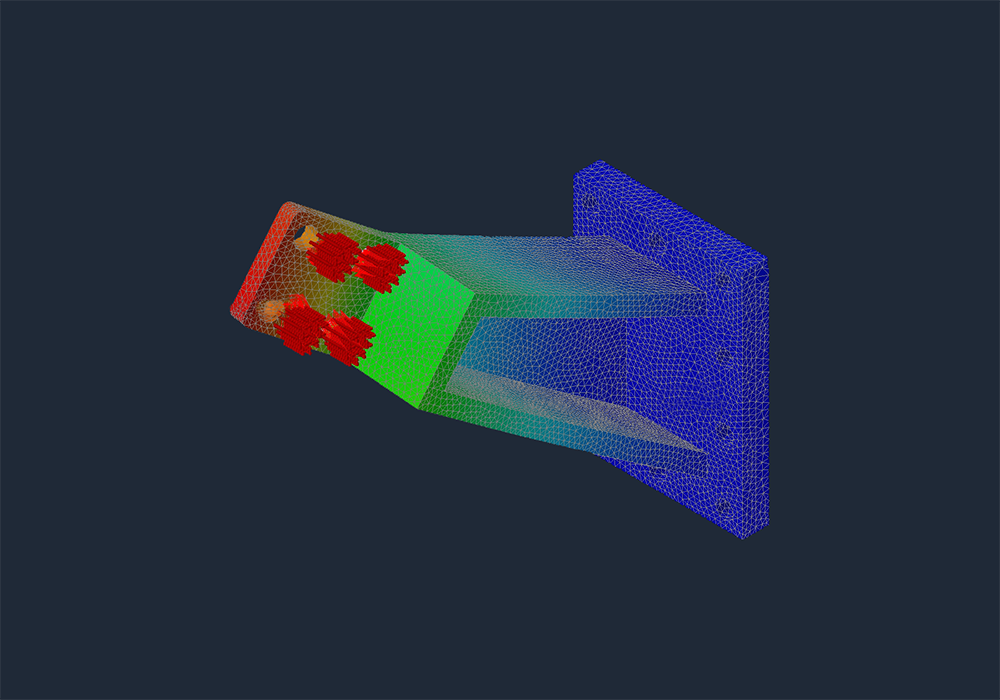

- FEA, Modal, & Thermal Analysis:

- Provide FEA, modal, and thermal analysis of the proposed solution to ensure resonance is avoided.

Ready to Learn More?

Schedule Your Free Consult Today

Testimonial

What Our Clients are Saying

“We were experiencing repeated bearing failures on one of our press felt rolls due to high vibration at a specific machine speed. The Vibration Engineers team identified this issue as a resonant condition and designed a solution that now allows us to operate reliably at this speed.”

Explore Our Full Vibration Analysis and Engineered Correction Guide

If you are seeing vibration issues on motors, fans, piping, turbines, or structural systems, this article covers only one piece of the diagnostic process. Our comprehensive Vibration Analysis and Engineered Correction guide shows how we use modal testing, ODS, FRFs, FEA, and field measurements to identify root causes and engineer permanent fixes.