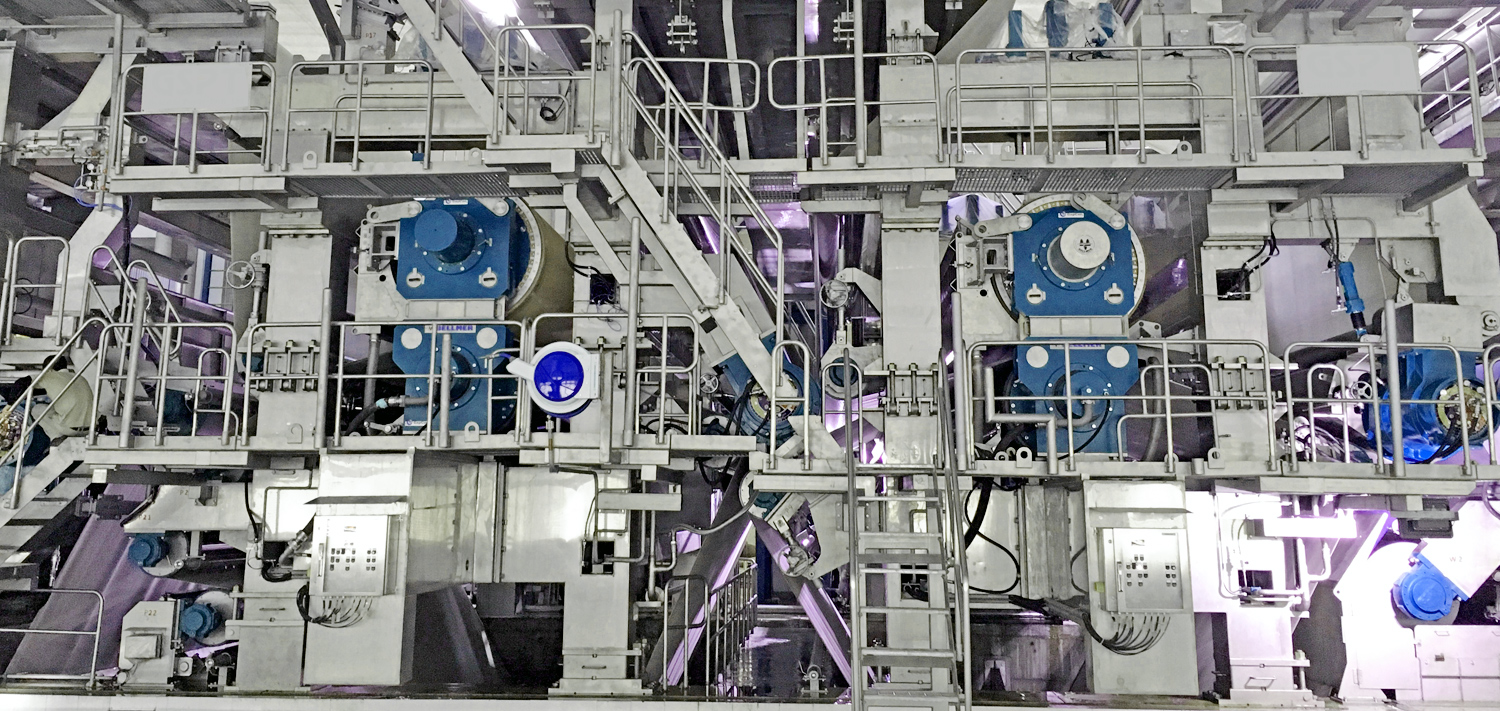

Press Roll Barring

If you're getting regular, repetitive marks, or patterns on your soft roll covers you've got press roll barring. Vibration Engineers can help you determine the cause and correct the issue.

We Can Help

How We Correct Press Roll Barring

These are the steps Vibration Engineers takes to review press roll barring issues and provide an engineered solution to correct the problem. Learn More

- Barring Review:

- Work with mill personnel to understand the barring of nipped rolls.

- Roll Information Gathering:

- Gather roll diameter and cover information, including PJ values and roll grind history.

- Testing Plan Development:

- Devise a test plan to acquire data on-site, including impact testing of roll covers, machine frames, and bearing housings.

- Caliper Data Assessment:

- Assess MD caliper data from the sheet property scanner to determine if caliper variation in the sheet is inducing roll barring.

- Critical Roll Ratio Assessment:

- Assess roll diameters for critical roll ratios.

- Vibration Data Analysis:

- Analyze vibration data to determine natural frequencies of the nip and barring severity.

- Assessment Report:

- Provide a full report of the assessment with recommendations for a path forward to correction.

Ready to Learn More?

Schedule Your Free Consult Today

Testimonial

What Our Clients are Saying

“We faced reduced cover life on several of our nipped rolls. Vibration Engineers helped us determine the optimum roll diameters, eliminating the risk of barring. This has resulted in significant cost savings.”

Explore Our Full Vibration Analysis and Engineered Correction Guide

If you are seeing vibration issues on motors, fans, piping, turbines, or structural systems, this article covers only one piece of the diagnostic process. Our comprehensive Vibration Analysis and Engineered Correction guide shows how we use modal testing, ODS, FRFs, FEA, and field measurements to identify root causes and engineer permanent fixes.