Vibration Engineers

Vibration Analysis & Engineered Correction

From diagnosis to correction. We do not just hand you a spectrum, we design and implement fixes that keep your plant running. Vibration Engineers is a white glove reliability partner that can be on a plane at a moment’s notice, delivering field data collection, advanced analysis, and engineered solutions for heavy industry.

Why Vibration Problems Persist

Vibration is not a single problem, it is a symptom. It emerges from structure, rotor dynamics, process transients, thermal growth, resonance, looseness, alignment, pulsation, and more.

Most vibration vendors stop at data collection. They hand you a report and leave you to figure out what to do with it.

We raise the bar by correlating field measurements with physical models and then engineering a real-world solution you can build, install, and maintain.

How We Work

Our workflow ensures vibration problems are understood, quantified, and corrected with engineering precision.

1.

Problem identification: We start by interviewing operators and maintenance staff, reviewing failure history, process conditions, and operating constraints.2.

Field measurements: We collect high quality data. Route and spot checks, multi channel transient runs, impact and operational modal testing, and pressure pulsation measurements where needed.3.

Correlation and root cause: We analyze frequency response functions, operational deflection shapes, and phase relationships, then correlate them to FEA and modal models. We review Campbell diagrams and check for critical speeds and resonant conditions.4.

Engineered solution: Once the root cause is clear, we design the fix. Structural modifications, bracing and stiffness changes, pedestal and foundation redesign, balancing and alignment plans, and support or restraint changes for piping.5.

Verification: After modifications, we repeat measurements to confirm vibration reduction, margin to resonance, and stress improvements. You get a clear before and after comparison and an acceptance report you can keep on file.

This structured diagnostic to correction process ensures that solutions are practical, buildable, verifiable, and proven in the field.

Core Vibration Services

Each service includes what it is, when to call, and where to learn more.

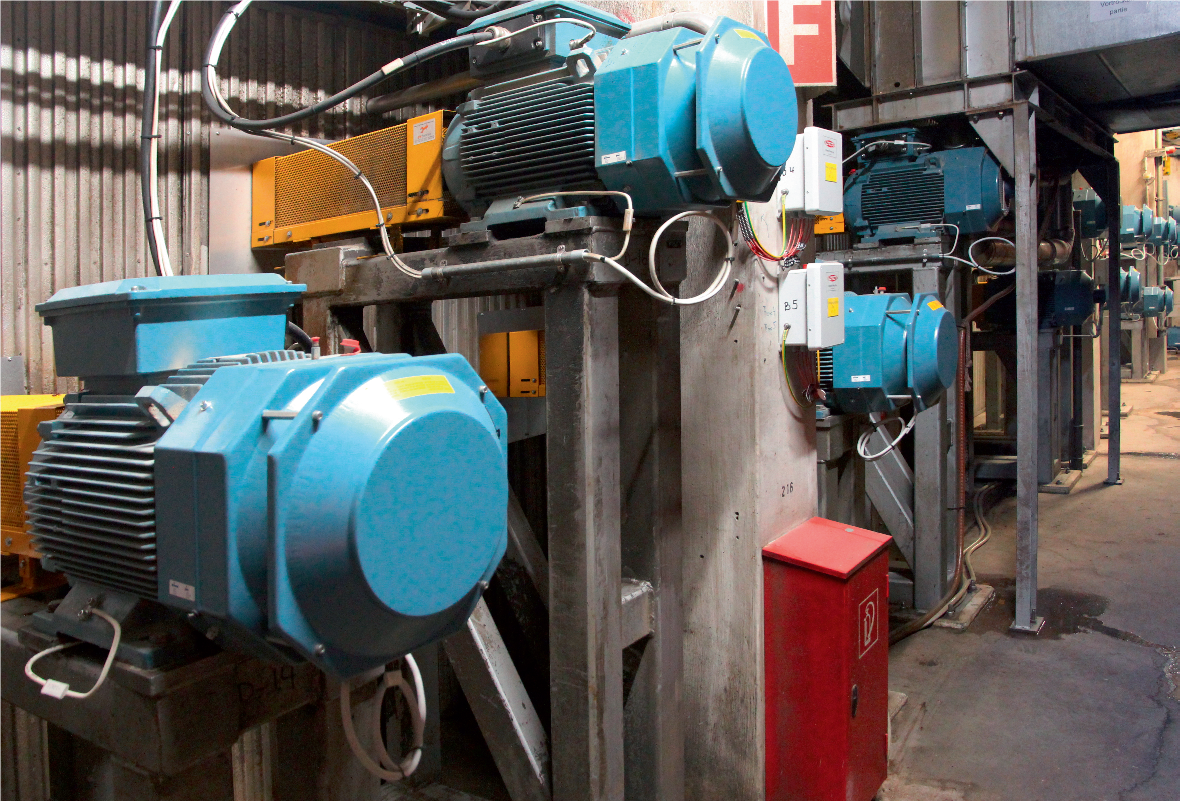

Drive Motor Pedestal Correction

Drive motor pedestals often develop structural weaknesses, degraded grout, or resonant modes that amplify vibration. Even a well aligned and balanced motor can fail prematurely if the pedestal cannot adequately support dynamic loads. Our service identifies these issues and delivers engineered structural improvements.

When to call

- Recurring failures on motors, gearboxes, or bearings

- Elevated amplitudes near one or more discrete speeds

- Floor borne vibration or noticeable movement in foundations or pedestals

What we do

- Dimensional assessment, often with laser scanning or as built review

- Impact and operational modal testing of pedestals, bases, and supporting structure

- FEA and modal analysis to identify resonant modes and weak points

- Engineered structural modifications, bracing, and damping strategies

- Verification testing with clear acceptance criteria

Deep Dive: Drive Motor Pedestal

Related Article: Drive Motor Pedestal Correction

Fan Vibration Correction

Fans and blowers are highly sensitive to imbalance, structural resonance, and alignment issues. Small defects can quickly escalate into bearing failures or unstable operation. We evaluate the whole system to separate rotor issues from structural drivers and provide durable corrections.

When to call

- Repeat bearing or seal failures

- High 1x vibration with unstable phase

- Balance jobs that do not hold or only help temporarily

- Casing or foundation resonance, cracked welds, or noisy operation

What we do

- In situ balancing with proper trial and trim runs

- Impact testing and operational deflection shapes to see how the fan, base, and structure move

- FEA and modal correlation to find modes too close to running speed

- Structural modifications and stiffness and damping changes

- Alignment, soft foot correction, and foundation recommendations

Deep Dive: Fan Vibration Correction

Related Article: Correcting Fan Vibration

Piping Vibration Correction

High energy piping systems develop vibration due to flow turbulence, pulsation, and structural resonance. These conditions can lead to fatigue cracking, failed supports, and safety risks. We identify the true forcing mechanisms and design reliable long term fixes.

When to call

- Cracked welds or small bore connection failures

- Broken supports, U bolts, or clamps

- Instrument failures or erratic readings

- High acoustic or flow induced vibration

What we do

- Multi channel vibration and strain measurements

- Transient testing and pulsation surveys for high energy lines

- Pipe stress and modal analysis to identify resonant spans

- Support, brace, and restraint redesign

- Fatigue screening and recommendations for code compliant solutions

Deep Dive: Piping Vibration Correction

Related Article: Correcting Vibration in Pipes

Machine Speed Increase

Machines often operate below their true capability due to resonant speeds or instability within their operating envelope. We help clients safely increase machine speed by identifying limiting modes and engineering structural or dynamic corrections.

When to call

- Production targets require running through historical no go speeds

- Machines are currently speed limited by vibration or chatter

- Prior attempts to raise speed have failed or created new vibration problems

What we do

- Baseline and raised speed testing

- Impact testing of frames, rolls, and supporting structure

- Identification of critical speeds and resonant modes

- Stiffness and bracing upgrades to move modes away from operating ranges

- Acceptance criteria and validation at the new target speed

Deep Dive: Machine Speed Increase

Related Article: How To Reliably Increase Machine Speed

Winder Reliability

Winder vibration affects product quality, limits operating speeds, and increases maintenance burden. We resolve vibration at its root by analyzing the dynamic behavior of rolls, frames, and supporting structure.

When to call

- The winder caps production because of vibration or chatter

- Set quality is limited by vibration induced defects

- Operators avoid certain speeds or profiles to prevent instability

What we do

- Transient vibration testing through wind profiles

- Operational deflection shapes and modal work on rolls and frames

- Structural modifications to separate machine modes from operating ranges

- Balance, alignment, and tension control recommendations

Deep Dive: Winder Reliability

Related Article: Improving Winder Reliability

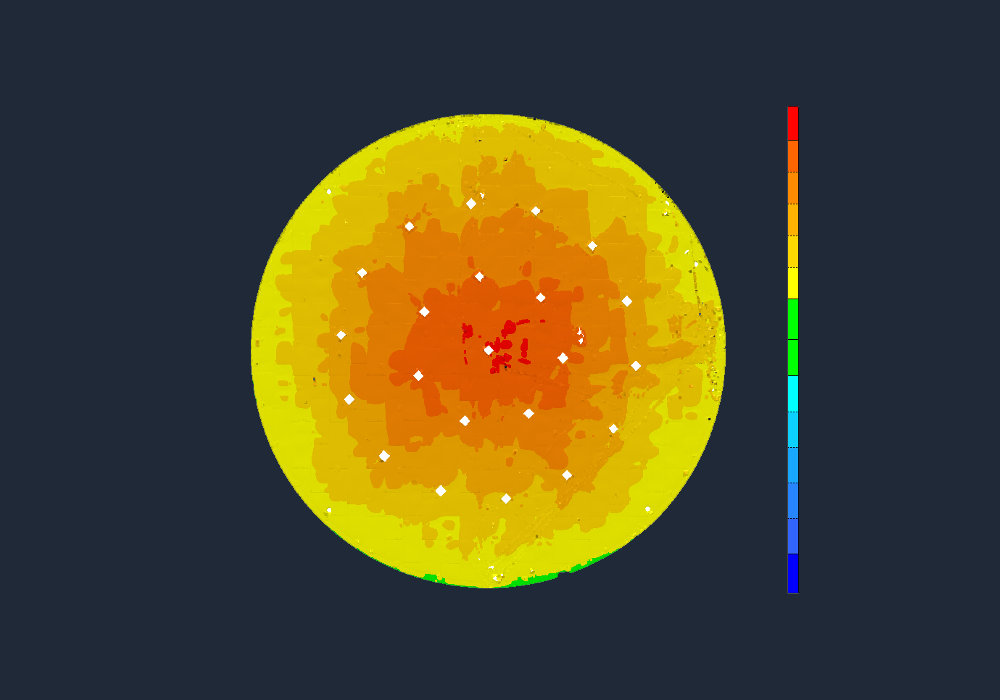

Vibrating Screens

Screens in mining and aggregates endure extreme loads that can trigger resonance, cracking, and premature fatigue. We identify dynamic weaknesses and design improvements for long term reliability.

When to call

- Deck or cross member cracking

- Fastener failures and broken attachments

- Excessive motion or unexpected mode coupling

- Short life on screen media

What we do

- Multi channel frequency response function measurements and operational deflection shapes

- FEA correlation to understand mode shapes and stress hot spots

- Stiffness, mass distribution, and damping improvements

- Recommendations for structural reinforcement and connection upgrades

Deep Dive: Vibrating Screens

Related Article: Improving Vibrating Screen Performance

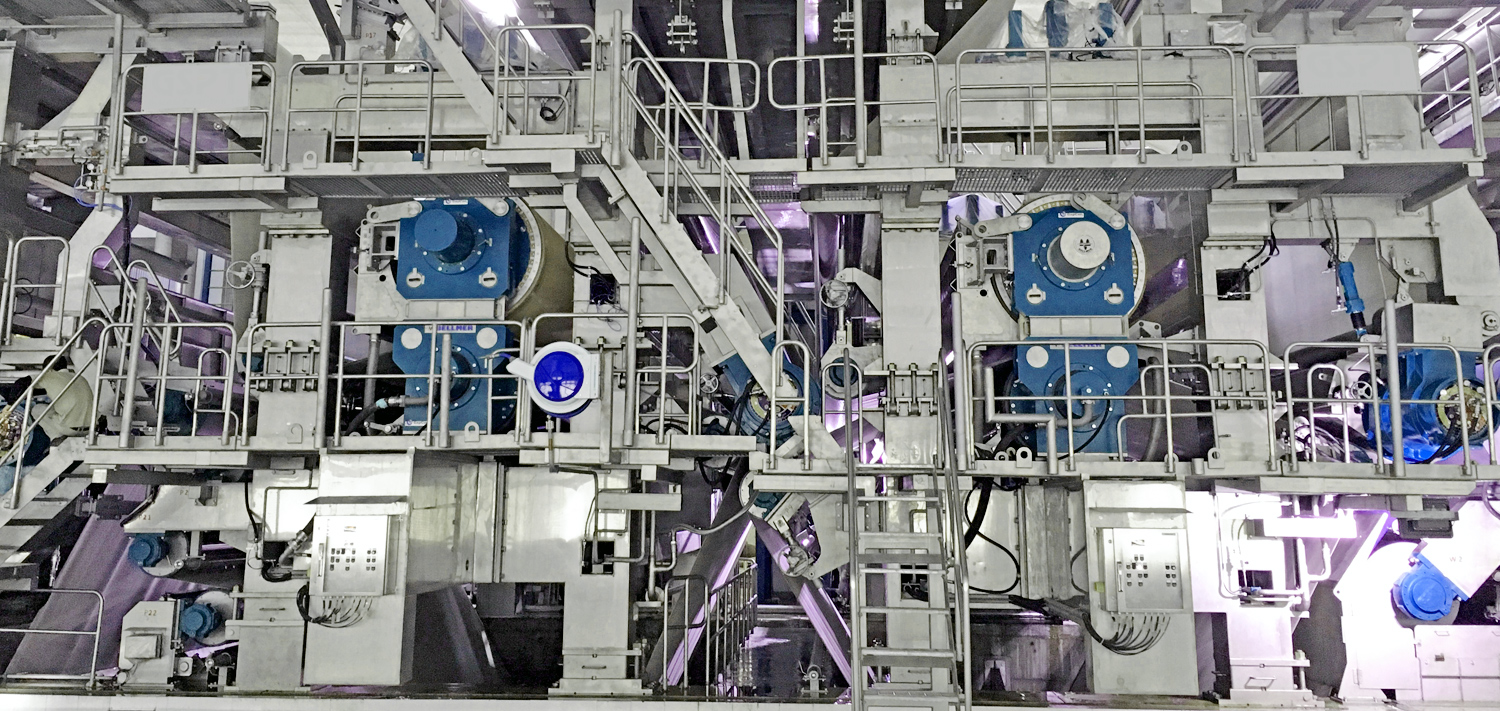

Press Roll Barring

Barring creates repeating marks and instability in press sections, often tied to resonance or structural flexibility. We determine whether the issue is mechanical, structural, or process related and design a stable long term fix.

When to call

- Repeating marks or patterns on soft roll covers

- Speed dependent barring behavior

- Quality or runnability issues traced to press section vibration

What we do

- Diagnostics to confirm barring versus other surface or process issues

- Resonance checks on rolls and supporting structures

- Structural and dynamic remedies to move problematic modes

- Balance and alignment plans where appropriate

Deep Dive: Press Roll Barring

Related Article: Solving Press Roll Barring

Stock Prep Pulsation

Pulsation in stock prep systems leads to sheet formation issues, headbox instability, and operational variability. We evaluate pumps, piping, tanks, valves, and controls to identify and eliminate pulsation sources.

When to call

- Sheet formation problems and paper quality issues

- Headbox instability or approach flow variability

- Frequent pressure related upsets or instrumentation noise

What we do

- Pressure and flow pulsation surveys with synchronized logging

- System impedance and layout review

- Pump and valve strategy assessment, including NPSH and cavitation risk

- Surge tank, pulsation dampener, and accumulator recommendations

- Control, PID, and deaeration strategies to stabilize flow

Deep Dive: Stock Prep Pulsation

Related Article: Solving Stock Prep Pulsation

Turbine Vibration Diagnostics

Turbines exhibit unique dynamic behavior, including rotor related vibration, casing flexibility, and support structure modes. We combine rotordynamics, structural testing, and proximity probe data for a full system diagnosis.

When to call

- Turbine trips, alarms, or trending vibration increases

- Sub synchronous vibration or suspected rotordynamic issues

- Worsened vibration after an outage or alignment job

- New or overhauled units that fail vibration acceptance tests

What we do

- Multi channel vibration and proximity probe measurements

- Orbit, Bode, and Campbell analysis

- Rotordynamic modeling and critical speed evaluation

- Casing and support structure modal testing where needed

- Engineered recommendations for safe, stable operation

Deep Dive: Turbine Vibration Diagnostics

Related Article: A Complete Guide to Turbine Vibration Diagnostics

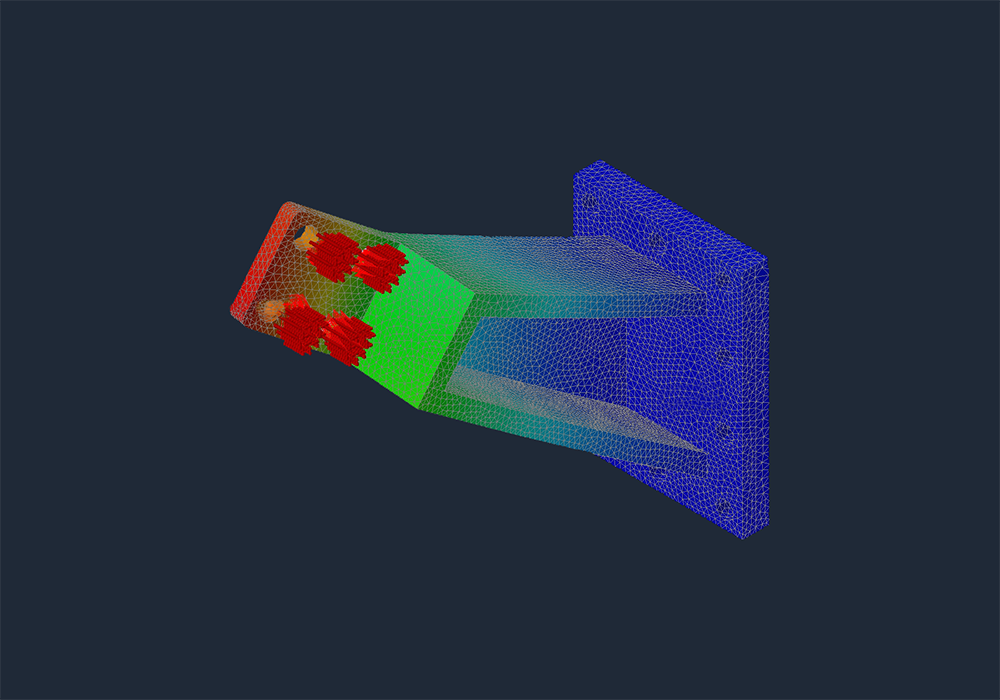

FEA, Modal, & Thermal Analysis

When structural resonance or design concerns arise, finite element and modal analysis provide clarity. We model and test components and assemblies to predict behavior, validate designs, and engineer improvements.

When to call

- Suspected resonance on new or existing equipment

- Planned structural changes or equipment upgrades

- Need to validate design before fabrication or installation

What we do

- Linear, modal, and thermal FEA

- Forced response studies and stress evaluation

- Mode placement and separation to avoid resonance

- Correlation of test data with models using modal assurance criteria

- Redesign and verification plans for long term reliability

Deep Dive: FEA And Modal Analysis

Related Article: How Modal Analysis Prevents Vibration

Fitness For Service

When equipment shows damage, corrosion, or distortion, fitness for service determines whether it is safe to continue operating. We perform API 579 evaluations backed by engineering analysis.

When to call

- Damage, corrosion, or flaws found in pressure vessels, tanks, or piping

- You need to know if equipment is safe to continue operation

- You want to avoid unnecessary replacement or downtime

What we do

- Fitness for service assessments to API 579

- Evaluation of corrosion, metal loss, cracking, deformation, and other damage mechanisms

- Use of appropriate assessment levels from screening through advanced analysis

- Stress analysis and, where needed, finite element analysis to quantify margins

- Practical recommendations for continued service, derating, repair, or replacement

Deep Dive: Fitness For Service

Related Article: A Complete Guide to Fitness for Service (API 579) Assessments

Laser Scanning And Reality Capture

Accurate geometry is essential for engineering analysis, retrofits, and shutdown planning. Our laser scanning and reality capture services provide precise as built data for modeling and design.

When to call

- No reliable as built models or outdated drawings

- Brownfield retrofits, tie ins, or complex piping additions

- Tight shutdown windows where you need to get it right the first time

What we do

- Tripod and mobile LiDAR and SLAM scanning

- Registered point clouds in standard formats

- Scan to CAD and scan to BIM models

- Dimensional control and deviation analysis

- Digital twin support for long term asset management

Deep Dive: Laser Scanning And Reality Capture

Related Article: A Complete Guide to Laser Scanning And Reality Capture

Questions?

Not sure which service fits your issue? Contact and describe the symptoms. We will point you in the right direction.

Technical Foundations

The Physics Behind Machinery Vibration

Rotating and reciprocating machines generate dynamic forces. When these forces align with natural frequencies in a structure, such as a pedestal, base, frame, piping run, or floor, vibration amplitudes rise sharply.

Many persistent vibration problems are not solved by balancing alone because the root cause is structural. A machine is a system of many coupled modes. Motors, gearboxes, fans, pumps, piping, pedestals, floors, and mezzanines each have natural frequencies. When operating or forcing frequencies align with those modes, resonance amplifies vibration.

Common Root Causes

- Resonance

- Unbalance and mass eccentricity

- Misalignment, including angular, offset, and soft foot conditions

- Mechanical looseness such as cracks, degraded grout, and poor bolting

- Bent shafts and journal defects

- Piping resonance and pulsation

- Process transients including load, speed, thermal, or pressure changes

Our job is to separate these influences and identify which ones actually drive the problem in your plant.

Field Data Collection

Route Based Testing

We perform route and spot measurements to build baselines, trend key indicators, and screen for developing faults. This is often the first step, not the last.

Multi Channel Impact Testing

Instrumented impact hammers and multi channel data recorders let us map frequency response functions across machines, structures, and piping systems. From this we identify:

- Natural frequencies

- Mode shapes

- Damping levels

- Areas of structural weakness

Operational Deflection Shapes

Operational deflection shape analysis shows how a machine or structure moves under real operating conditions. This is critical when resonance is excited by process loads, not just an external tap.

Operational Modal Analysis

For turbines, large frames, and piping systems, we often extract modal parameters while the equipment is running. This avoids long outages and provides realistic boundary conditions.

Transient Run Up And Coast Down Analysis

Where safe, we acquire data as machines speed up or slow down through critical ranges. This helps identify critical speeds, sub synchronous phenomena, and speed dependent instabilities.

Need Modal, ODS, or FRF Testing?

Speak with our engineering team at 702-518-2998 or message below.

Engineering Analysis: FEA, Modal, Thermal, and Correlation

Finite Element Analysis

Using tools such as Autodesk Inventor Nastran, we model:

- Natural frequencies and mode shapes

- Support stiffness and boundary conditions

- Forced response under realistic loading

- Stress ranges and fatigue risk

Modal Correlation Between Test And Model

We correlate test data, such as frequency response functions and operational deflection shapes, with FEA models using:

- Frequency matching

- Mode shape comparison

- Modal assurance criteria

Good correlation means we can trust the model when designing modifications.

Correction Engineering

Once root causes are clear, we design practical fixes:

- Increased stiffness at key locations

- Modified bracing and load paths

- Reinforced pedestals and baseplates

- Structural steel upgrades and connection improvements

- Damping strategies and isolation where appropriate

- Piping supports, guides, and restraints designed to code

Every recommendation is supported by calculations, sketches or drawings, and clear acceptance criteria.

Fan And Blower Balancing

Balancing fans and blowers is one of the most visible vibration fixes in a plant, but it is often misunderstood. Many balance jobs fail because they treat imbalance as the only issue, when structural resonance, looseness, or misalignment are also present. Our approach to balancing starts by confirming that imbalance is really the main driver.

We combine vibration data, phase relationships, impact testing, and operational deflection shapes to separate imbalance from structural problems. When we confirm that balance is a major contributor, we plan and execute the balancing work in a controlled way.

Our fan and blower balancing process typically includes:

- Reviewing vibration spectra and phase data to confirm imbalance signatures

- Checking for structural resonance that could mask or amplify imbalance

- Planning trial weights that are large enough to measure but still safe

- Performing single plane or two plane balancing as appropriate for the rotor

- Using influence coefficient methods where needed for coupled planes

- Verifying final levels against realistic acceptance criteria based on speed, size, and bearing type

- Documenting as found and as left conditions, including weights and final vibration levels

Because balancing is integrated with our structural and modal work, the outcome is more than a quick reduction in numbers on a screen. The goal is a fan or blower that runs smoothly over the long term, with both the rotor and its supporting structure operating in a stable, predictable way.

Have a Fan or Blower That's Constantly Out of Balance?

Call us to discuss the problem or message us below. 702-518-2998

Industry Expertise

Pulp And Paper

We support press sections, dryers, reels, winders, and stock prep systems. Vibration and pulsation issues often show up as quality problems, speed limits, or short maintenance intervals.

Mining And Aggregates

Screens, crushers, feeders, and conveyors experience heavy duty loading and fatigue risk. We help identify structural modes, reduce cracking, and improve availability.

Power And Process

Turbines, pumps, compressors, and process piping all face resonant risks and fatigue concerns. We combine rotordynamics, structural dynamics, and pulsation work to keep them stable.

Marine And Offshore

Hull and propulsion vibration affects comfort, reliability, and safety. We perform operational deflection and modal work on hulls, shafts, supports, and deck structures to guide retrofits and upgrades.

Case Studies

Vibrating Screens

We were engaged to help improve the service life of one vibrating screen design. The screens were seeing higher than expected stresses and premature cracking in critical members.

We performed impact testing and operational deflection shape analysis to understand how the screen behaved under load. That data was used to build and refine FEA and modal models of the structure.

With test correlated models in hand, we worked to adjust stiffness, mass distribution, and local details so that critical modes were moved away from operating ranges. The result was a more robust screen design with improved service life and reduced risk of fatigue failures in the field.

ODS And Modal Testing For Blower

We were asked to help diagnose persistent vibration and balance issues on a critical fan. There were ongoing reliability concerns, and previous balance jobs had not delivered lasting improvement.

We performed impact testing and ODS work on the fan support structure and surrounding steel, combined with close review of fan vibration data. The testing showed that structural resonance was amplifying vibration near running speed.

Based on the test and analysis results, we outlined structural changes and then returned to perform a controlled balance on the fan. The combination of structural improvement and a proper balance job delivered a stable operating condition and reduced vibration levels to acceptable values.

Fan Balancing

We were brought in to address vibration on process fans that were limiting reliability and increasing maintenance effort.

We confirmed that imbalance was a significant driver by reviewing vibration signatures, phase data, and structural behavior. Once imbalance was confirmed as a key contributor, we carried out in situ single plane and two plane balance jobs on the affected fans.

Balanced fans with appropriate acceptance criteria, combined with basic alignment and support checks, allowed the client to run their process fans more smoothly, extend bearing life, and reduce the number of unscheduled interventions.

Felt Roll Resonance

Our team was asked to investigate vibration on felt rolls that was affecting machine performance. Operators had identified speed ranges that were best avoided, but the underlying resonance issues were not fully understood.

We performed bump testing on the felt rolls and supporting structure to identify natural frequencies and mode shapes. Those test results were used to build and correlate FEA and modal models of the brackets and supports.

Using those models, we redesigned the bracket geometry so that its natural frequencies were moved outside the operating range of the machine. The redesigned supports reduced the risk of resonance and helped avoid future vibration issues in the speed ranges that mattered most.

Machine Speed Increase And Long Term Production Planning

For several clients, machine vibration limited the speed they were comfortable running, which in turn affected long term production planning. These clients wanted the confidence to plan decades of production on the assumption that machines could run reliably at higher speeds.

We approached these projects by combining transient vibration testing, modal analysis, and FEA based structural review. Critical speeds and resonant modes were identified and separated from the desired operating envelope through targeted structural changes, bracing, and in some cases balance and alignment improvements.

Once the machines were operating stably at the new speeds, we documented the analysis, modifications, and acceptance results. This gave our clients the technical basis they needed to build and defend long term production plans tied to those upgraded assets.

Have a Similar Problem?

Give us a call to speak with one of our engineers about your issue. 702-518-2998

Tools And Instrumentation

We use a combination of:

- Multi channel vibration analyzers and recorders

- Instrumented impact hammers and single axis accelerometers

- Proximity probes and keyphasor signals on turbines

- Autodesk Inventor Nastran and related FEA tools

- LiDAR and SLAM scanners for reality capture

- High speed video and motion amplification where appropriate

These tools let us move from it vibrates to here is the specific physical change that will fix it.

Frequently Asked Questions

-

1. Do you only collect data?

No. Data collection is the starting point. We collect, analyze, engineer the fix, and verify results in the field.

-

2. Can you travel on short notice?

Yes. We frequently fly on short notice for urgent failures, turnarounds, and high priority projects.

-

3. Will you work with our OEM, EPC, or internal engineering group?

Yes. We coordinate with your OEM, EPC, and engineering teams and provide models, drawings, and reports in formats they can use.

-

4. Can you validate raised speed operation?

Yes. We develop acceptance criteria and perform testing at the new operating speeds to confirm margin to resonance and stable behavior.

-

5. Do you provide drawings and reports?

Yes. All engineered corrections are documented with analysis, recommendations, and clear acceptance criteria.

-

6. How long does a typical vibration diagnostic project take from first call to final report?

Most projects can begin within a few days of first contact, and initial on site work is often completed in one to two days depending on the size of the machine or system. Data analysis, modeling, and the final report typically take an additional three to seven days. Larger or multi machine studies may require more time, but we work closely with you to align timelines with your outage windows and operational needs.

-

7. What do you need from us before you come on site?

A brief history of the issue, recent vibration data if available, operating conditions, and any prior work or changes are helpful. Drawings and as built information improve accuracy but are not required. Our team can also bring laser scanning equipment when dimensional details are unknown or outdated.

-

8. Can you work under tight turnaround or outage windows?

Yes. We frequently support emergency callouts and compressed outage schedules. Our workflow is built around fast mobilization, rapid data collection, and same day or next day preliminary findings when needed.

We're Here For You

Founder Details

Jon Thornham

702-518-2998

Jon Thornham is the founder of Vibration Engineers, a professional mechanical engineer, and entrepreneur focused on solving complex vibration and reliability challenges across industrial sectors.