Solving Press Roll Barring

Learn all about press roll barring in paper machines and how to solve the problem.

Jon Thornham

Founder

Machine Speed Increase

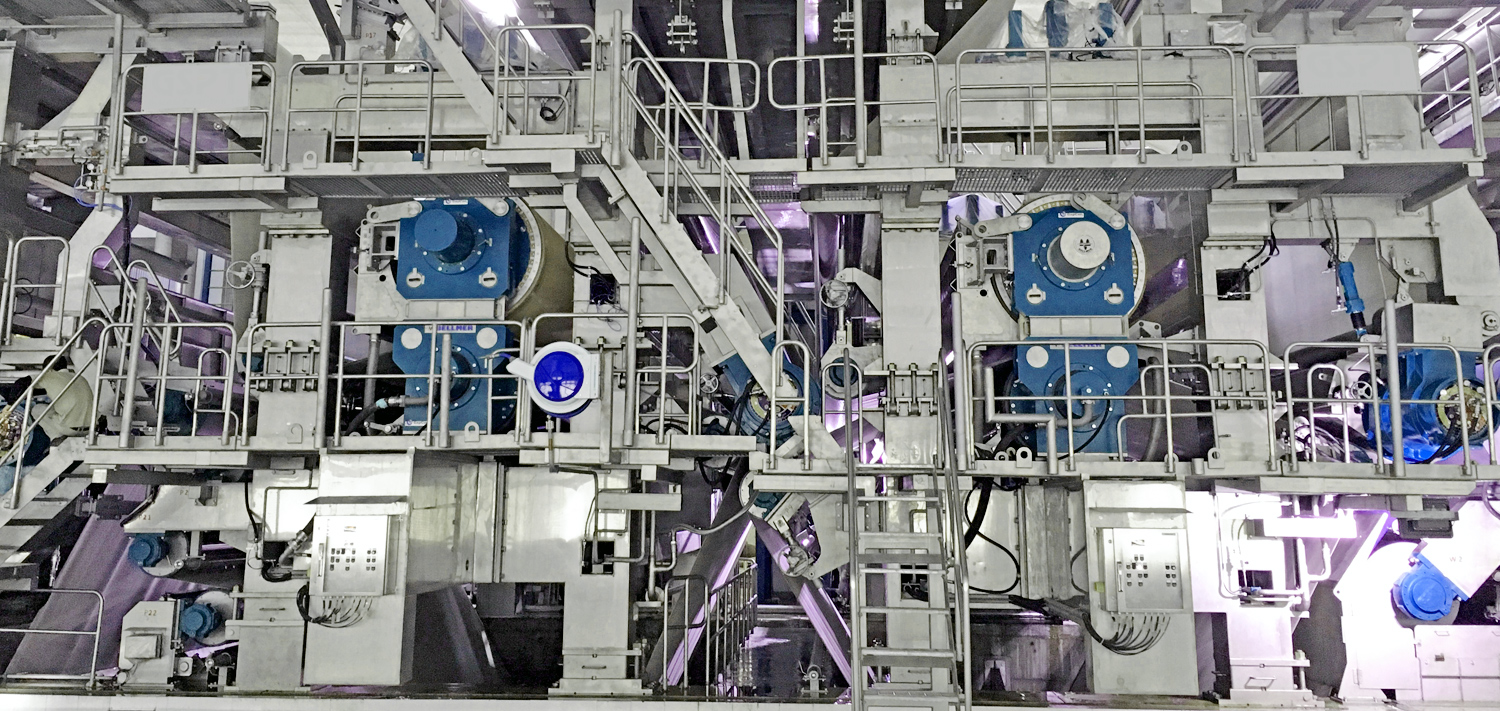

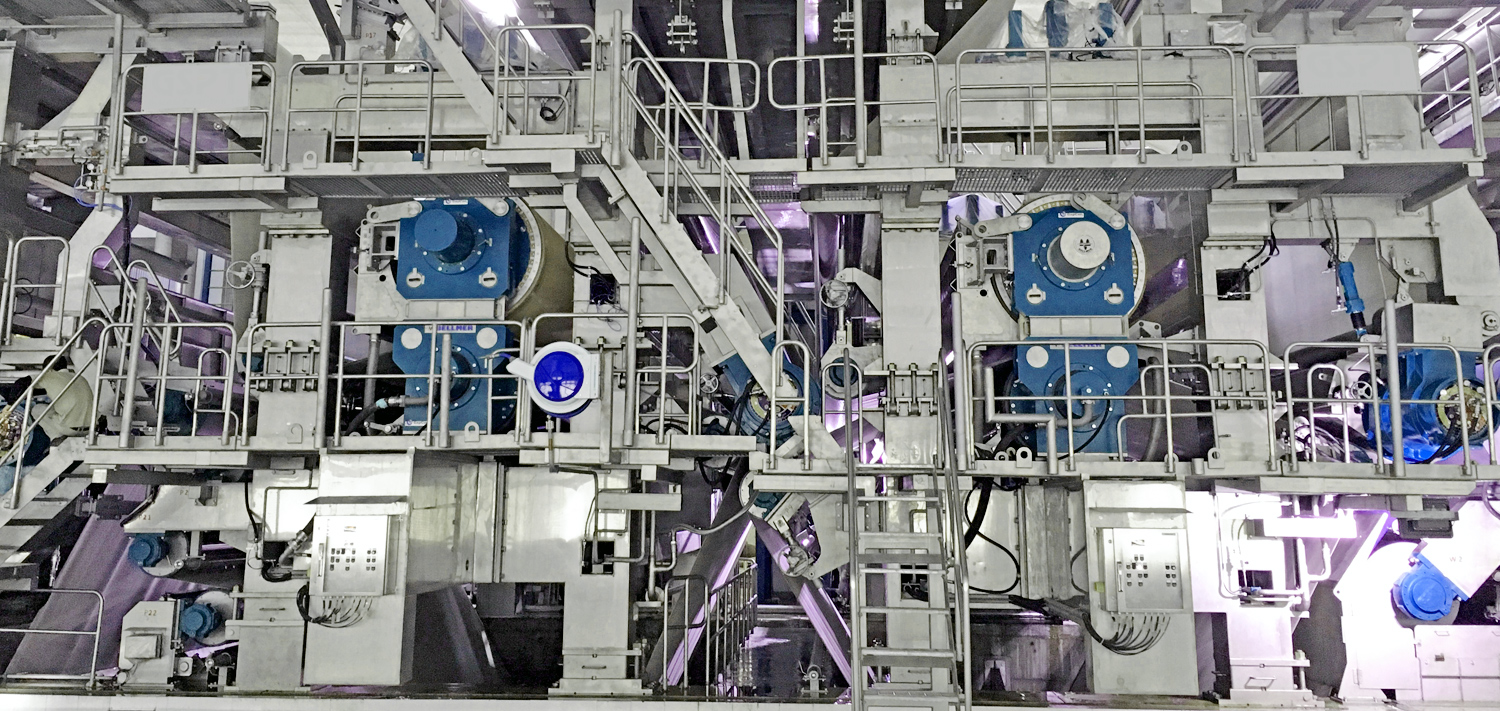

In the competitive landscape of the paper manufacturing industry, increasing production speed is a key objective for many companies. The dryer section of a paper machine, which removes water from the paper web through a combination of heat and airflow, is a critical component in this process. Enhancing the speed of this section can significantly boost overall production capacity. However, this endeavor involves careful consideration of several factors, including machine vibrations, roll replacements, and potential frame modifications. This article explores the comprehensive approach required to increase the production speed of a paper machine dryer section effectively and safely.

The dryer section is typically the longest part of a paper machine, consuming more energy than any other section. Its primary function is to reduce the moisture content of the paper web from around 60% after the press section to less than 10%. The efficiency and speed of this section directly impact the machine’s overall productivity and the quality of the final product. Increasing the speed of the dryer section can lead to higher output and improved profitability, but it must be approached with a thorough understanding of the challenges and potential solutions.

One of the critical considerations when increasing the speed of the dryer section is the impact on machine vibrations. At higher speeds, even minor imbalances or misalignments can cause significant vibration issues, leading to mechanical failures, reduced paper quality, and safety hazards. Therefore, conducting comprehensive vibration testing at the proposed increased speeds is essential.

Vibration analysis helps in identifying and diagnosing issues related to imbalance, misalignment, resonance, bearing failures, and other mechanical problems. By performing vibration testing, it is possible to detect these issues early and implement corrective measures before they escalate into more serious problems.

1.

Baseline Measurement: Measure the current vibration levels of the dryer section at the existing operating speed to provide a baseline for future comparisons.2.

Incremental Speed Increase: Gradually increase the speed of the dryer section while continuously monitoring vibration levels to identify the speed at which vibrations exceed acceptable limits.3.

Detailed Analysis: Use advanced vibration analysis tools to pinpoint the sources of excessive vibrations by examining the rolls, bearings, gears, and other components of the dryer section.4.

Implementation of Solutions: Implement solutions such as rebalancing rolls, aligning components, and replacing worn-out parts. Install vibration dampening devices to reduce the impact of vibrations.5.

Verification: Conduct another round of vibration testing to ensure the issues have been resolved and that the dryer section can operate smoothly at the increased speed.Rolls play a crucial role in the dryer section, supporting and guiding the paper web through the drying process. At higher speeds, the performance and stability of these rolls become even more critical. Replacing existing rolls with those designed to handle higher speeds is often necessary to achieve increased production rates.

1.

Material Selection: Rolls made from high-strength materials such as steel or composite materials are better suited for high-speed operations due to greater durability and resistance to wear and tear.2.

Surface Coatings: Applying advanced surface coatings to rolls can enhance their performance by reducing friction and improving heat transfer, leading to more efficient drying and smoother operation at higher speeds.3.

Precision Engineering: High-speed rolls should be engineered with precision to ensure perfect balance and alignment, minimizing the risk of vibrations and mechanical failures at elevated speeds. Determining the critical speeds of the existing rolls is key to understanding how rolls will respond to the increased machine speed.Replacing rolls requires careful installation and alignment to ensure optimal performance. Misaligned rolls can cause excessive vibrations, uneven drying, and damage to the paper web. Therefore, it is essential to follow best practices in roll installation, including:

1.

Precision Alignment Tools: Use laser alignment tools to achieve precise alignment of rolls.2.

Regular Maintenance: Implement a regular maintenance schedule to check for signs of wear and misalignment and make necessary adjustments.Let us help you increase machine speed while maintaining reliable production.

Increasing the speed of the dryer section can place additional stress on the machine’s frame and support structures. Therefore, frame modifications may be necessary to ensure the machine can handle the increased loads and vibrations associated with higher speeds and to shift natural frequencies out of the range of excitation.

Before making any modifications, it is essential to assess the current structural integrity of the dryer section. This involves:

1.

Inspection: Conduct a thorough inspection of the frame and support structures to identify any signs of wear, corrosion, or damage.2.

Stress Analysis: Perform a stress analysis to determine how the increased speed will impact the structural components. This can involve using finite element analysis (FEA) to simulate the stresses, identify potential weak points, and determine the natural frequencies of the existing structure.Based on the assessment, implement the necessary structural enhancements to strengthen the dryer section. This may include:

1.

Reinforcing Key Areas: Reinforce key areas of the frame and support structures to withstand the increased loads and vibrations.2.

Upgrading Materials: Replace existing structural components with those made from stronger, more durable materials.3.

Adding Supports: Add additional supports or braces to distribute the loads more evenly and reduce stress on individual components.When making frame modifications, it is crucial to ensure that all changes comply with safety standards and regulations. This includes:

1.

Engineering Approvals: Obtain necessary approvals from qualified engineers to ensure the modifications meet safety and performance standards.2.

Regular Inspections: Conduct regular inspections to verify that the modifications remain in good condition and continue to meet safety requirements.In addition to vibration testing, roll replacements, and frame modifications, integrating advanced technologies can further enhance the performance and efficiency of the dryer section at higher speeds.

Implementing advanced automation and control systems can help optimize the operation of the dryer section. This includes:

1.

Automated Monitoring: Use automated monitoring systems to continuously track key parameters such as temperature, humidity, and vibration levels, allowing for real-time adjustments to maintain optimal operating conditions.2.

Predictive Maintenance: Implement predictive maintenance systems that use data analytics and machine learning to predict when components are likely to fail and schedule maintenance before issues arise.Enhancing energy efficiency is another critical factor in optimizing the performance of the dryer section at higher speeds. This can involve:

1.

Heat Recovery Systems: Install heat recovery systems to capture and reuse waste heat from the dryer section, reducing energy consumption and lowering operating costs.2.

Insulation Improvements: Improve insulation in the dryer section to minimize heat loss and enhance drying efficiency.Increasing the production speed of a paper machine dryer section is a complex but achievable goal. It requires a comprehensive approach that includes vibration testing, roll replacements, and frame modifications to mitigate resonance. By carefully addressing these factors, paper manufacturers can enhance the efficiency and productivity of their machines while maintaining high standards of safety and paper quality.

Through meticulous planning, regular maintenance, and continuous monitoring, the challenges associated with higher operating speeds can be effectively managed. The result is a more efficient and productive paper manufacturing process, capable of meeting the demands of a competitive market and delivering high-quality paper products.

If you are seeing vibration issues on motors, fans, piping, turbines, or structural systems, this article covers only one piece of the diagnostic process. Our comprehensive Vibration Analysis and Engineered Correction guide shows how we use modal testing, ODS, FRFs, FEA, and field measurements to identify root causes and engineer permanent fixes.

Learn all about press roll barring in paper machines and how to solve the problem.

Jon Thornham

Founder

Author Details

Founder

Jon Thornham is the founder of Vibration Engineers, a professional mechanical engineer, and entrepreneur focused on solving complex vibration and reliability challenges across industrial sectors.