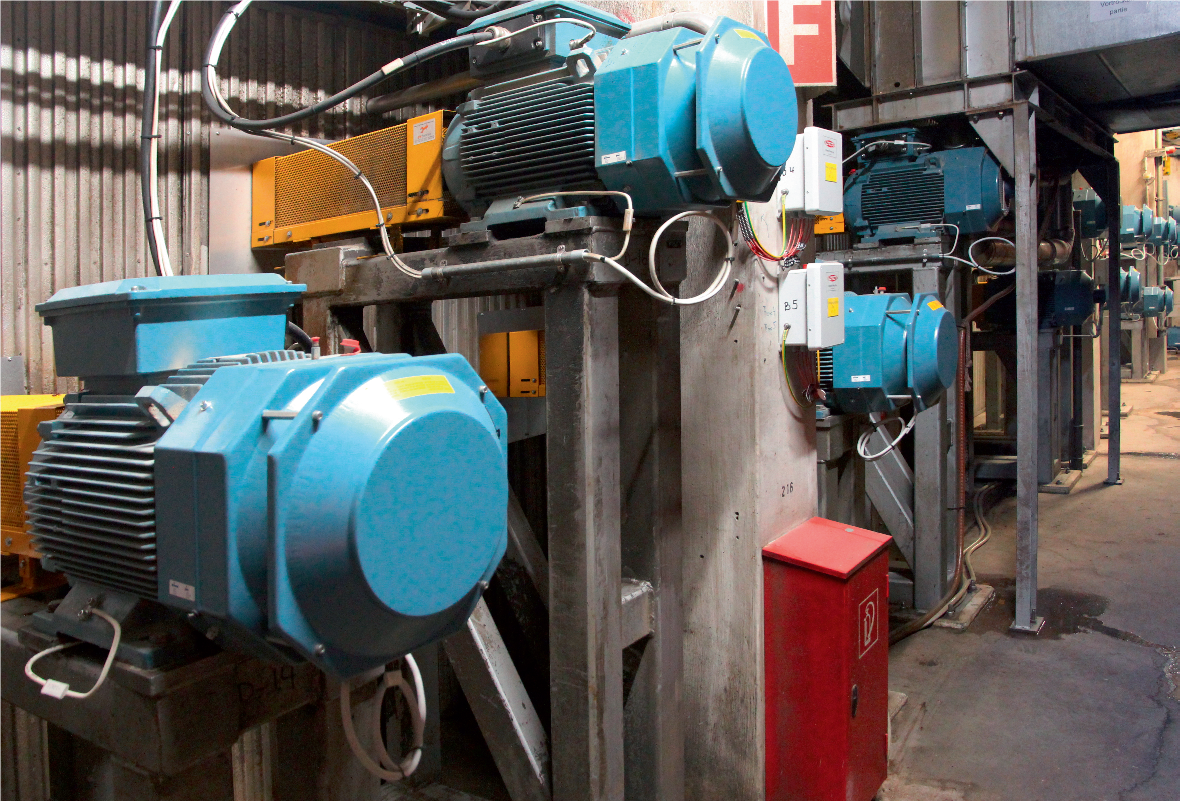

Drive Motor Pedestal Correction

If you're failing drive motors, gearboxes, or bearings you likely have a resonance issue with your motor pedestal or floor structure. Vibration Engineers can provide an engineered solution to correct the issue.

We Can Help

How We Correct Drive Motor Pedestals

These are the steps Vibration Engineers takes to diagnose drive motor pedestal issues and provide an engineered solution to correct the problem. Learn More

- Problem Identification:

- Work with mill personnel to identify current problems and assess past failures.

- Testing Plan Development:

- Devise a testing plan to gather vibration data on-site, including forced response testing or multichannel transient data collection.

- Data Post-Processing:

- Post-process vibration data for diagnosis of the problem.

- Assessment Report:

- Provide a full report of the assessment with recommendations for a path forward to correction.

- Dimensional Assessment:

- Perform dimensional assessment using a laser scanner to create a 3D model of the existing structure.

- Conceptual Sketches:

- Provide conceptual structural sketches of a proposed solution for review with the facility.

- FEA & Modal Analysis:

- Provide FEA & modal analysis of the proposed solution to ensure resonance is avoided.

Ready to Learn More?

Schedule Your Free Consult Today

Testimonial

What Our Clients are Saying

“The team at Vibration Engineers delivered exceptional service for our plant. We highly recommend their expertise.”

Explore Our Full Vibration Analysis and Engineered Correction Guide

If you are seeing vibration issues on motors, fans, piping, turbines, or structural systems, this article covers only one piece of the diagnostic process. Our comprehensive Vibration Analysis and Engineered Correction guide shows how we use modal testing, ODS, FRFs, FEA, and field measurements to identify root causes and engineer permanent fixes.