A Complete Guide to Fitness for Service (API 579) Assessments

Learn all about API 579 Fitness for Service assessments.

Jon Thornham

Founder

Vibrating Screens

Vibrating screens are essential components in various industrial processes, especially in mining and aggregate production. Their primary function is to separate different sizes of material efficiently. However, their reliability is crucial for maintaining production efficiency and minimizing downtime. This blog post delves into vibrating screen reliability, the role of vibration analysis, the importance of orbit plots, and the concept of resonance.

Vibrating screens must endure significant mechanical stress due to the intense vibrations they experience during operation. The reliability of these screens is paramount to ensure continuous production and to avoid costly downtime. Regular maintenance and monitoring are key to extending the lifespan of vibrating screens and ensuring their efficient operation.

Incorporating advanced monitoring systems can significantly enhance screen reliability. These systems provide real-time data on screen performance, allowing operators to detect issues early and prevent unplanned shutdowns.

Vibration analysis is a powerful tool used to monitor the condition of vibrating screens. It helps identify potential problems before they escalate into major failures. The process involves measuring the amplitude, frequency, and direction of the vibrations to assess the screen's health.

The importance of regular vibration analysis cannot be overstated. By understanding the vibration patterns, operators can pinpoint issues such as imbalances, misalignment, or bearing failures. This proactive approach helps in scheduling maintenance activities at optimal times, reducing the risk of unexpected breakdowns.

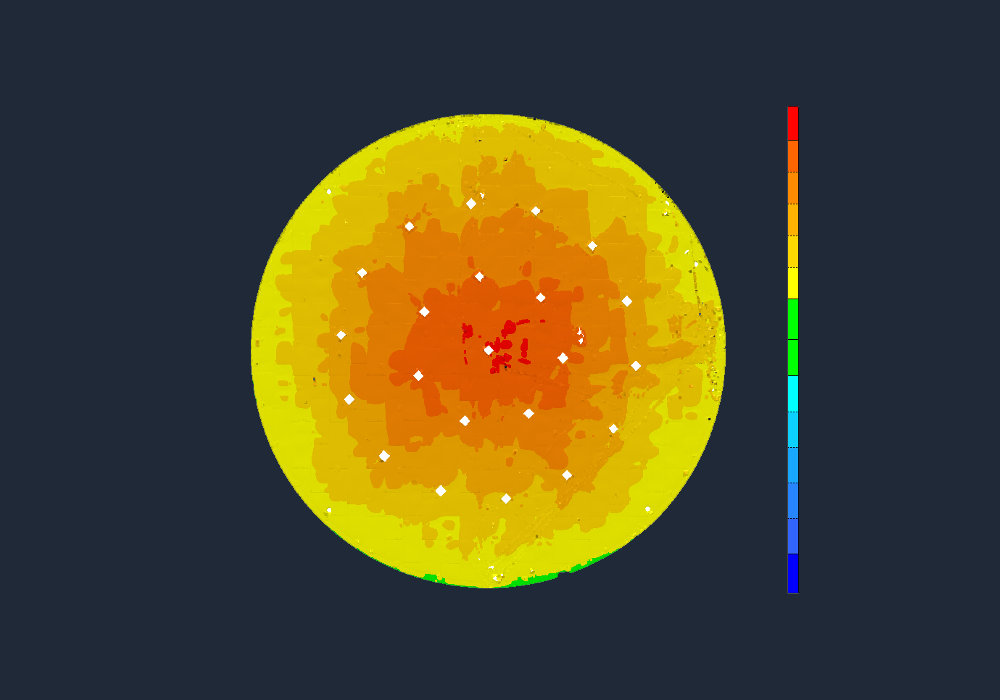

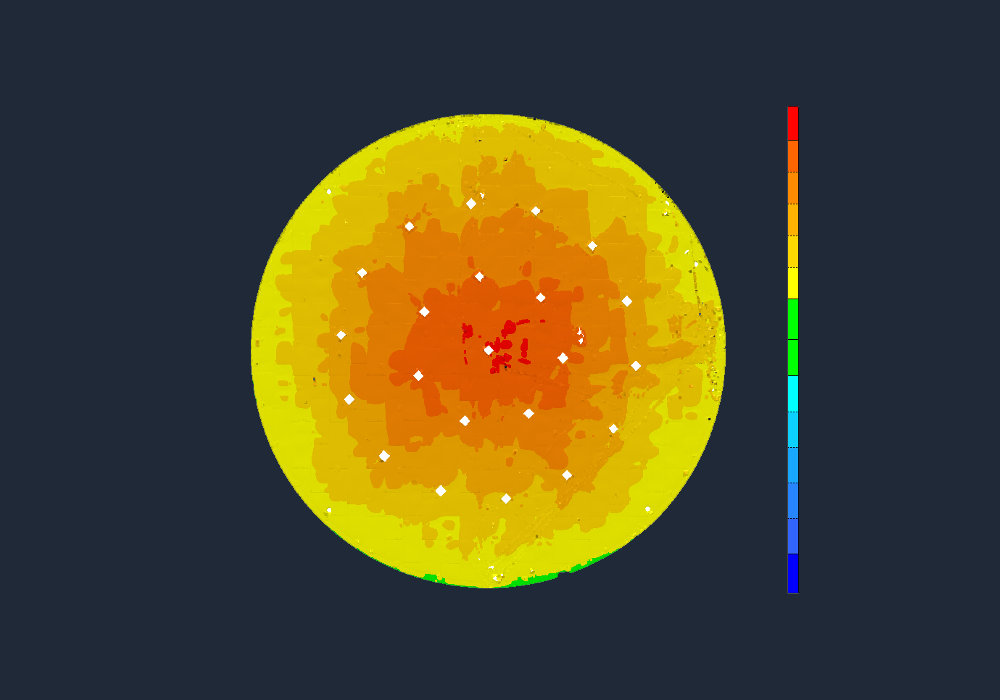

A Screen Motion Analyzer (SMA) is an example of a tool that aids in vibration analysis. It provides detailed insights into the performance of vibrating screens, helping operators develop predictive maintenance strategies. This tool collects data in real-time, allowing for quick identification of potential issues and facilitating timely interventions.

Orbit plots are graphical representations of the motion of a vibrating screen. They are used to visualize the trajectory of the screen's movement and to identify any irregularities. An orbit plot typically displays the horizontal and vertical displacements of the screen over time.

By analyzing orbit plots, operators can detect patterns that indicate mechanical issues. For instance, an elliptical orbit might suggest an imbalance, while a more erratic pattern could point to loose components or structural damage. Regularly monitoring orbit plots helps in maintaining the mechanical integrity of the vibrating screen and ensuring its optimal performance.

Resonance is a phenomenon that occurs when the natural frequency of a vibrating screen matches the frequency of its operating vibrations. When resonance occurs, the amplitude of the vibrations can increase dramatically, leading to excessive stress on the screen and potential failure.

Avoiding resonance is critical for the longevity of vibrating screens. During the design phase, engineers must ensure that the operating frequency is set away from the natural frequencies of the screen components. Additionally, regular vibration analysis can help detect if the screen is approaching resonance conditions, allowing for corrective actions to be taken promptly.

Let us help you analyze your screens and tune their performance.

Ensuring the reliability of vibrating screens is vital for maintaining efficient production processes. Incorporating advanced monitoring systems and utilizing tools like the Screen Motion Analyzer for regular vibration analysis can significantly enhance the lifespan and performance of these screens. By understanding and addressing issues related to orbit plots and resonance, operators can prevent costly downtime and ensure smooth operations.

Regular maintenance, supported by detailed vibration analysis, helps in identifying potential problems early and enables the development of effective predictive maintenance strategies. By staying informed and proactive, industries can optimize their vibrating screen operations, reduce maintenance costs, and enhance overall productivity.

For more detailed information on vibrating screen reliability and maintenance, you can explore various industry resources and tools available on the respective websites of leading companies.

If you are seeing vibration issues on motors, fans, piping, turbines, or structural systems, this article covers only one piece of the diagnostic process. Our comprehensive Vibration Analysis and Engineered Correction guide shows how we use modal testing, ODS, FRFs, FEA, and field measurements to identify root causes and engineer permanent fixes.

Learn all about API 579 Fitness for Service assessments.

Jon Thornham

Founder

Author Details

Founder

Jon Thornham is the founder of Vibration Engineers, a professional mechanical engineer, and entrepreneur focused on solving complex vibration and reliability challenges across industrial sectors.